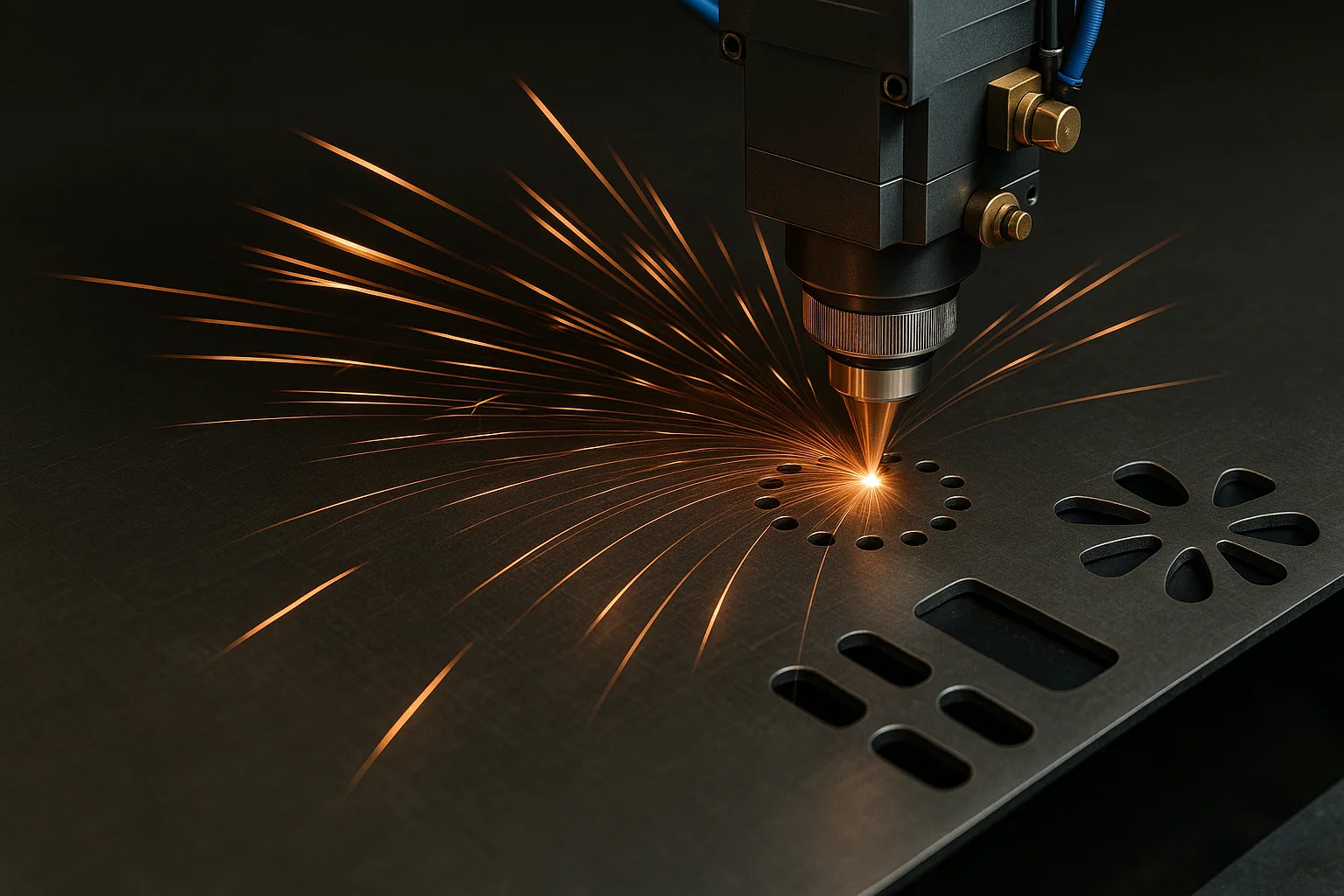

We perform laser cutting of sheet metal of any complexity:

- Steel, stainless steel, aluminum, brass, copper and other alloys

- Thickness up to 25 mm, workpiece length up to 6 m

- Minimal cutting roughness, no thermal deformations

- Cutting small holes, complex contours, shapes

- Rapid production of prototypes and serial batches

Modern Fiber Laser machines guarantee precision and repeatability of sizes throughout the entire print run.

Modern sheet metal bending presses allow you to create parts of any complexity:

- Precise bending angles – up to 0.5°

- Bending according to individual drawings and sketches

- Serial production of elements: cases, boxes, brackets, profiles

- Edge processing after cutting: deburring, chamfering, grinding

Each part is checked for compliance with dimensional tolerances.

Professional welding of metal structures of any complexity:

- MIG/MAG, TIG and spot welding

- Assembly of frames, cases, furniture, outdoor advertising

- Welding of non-ferrous and stainless metals

- Sealing and strength control of seams

We work according to GOST. It is possible to deliver “turnkey” with further processing and painting.

We offer finishing services:

- Powder coating in any RAL color

- Priming, phosphating, anti-corrosion protection

- Sandblasting and surface preparation

- Resistance to mechanical and atmospheric influences

The coatings undergo thickness and adhesion control according to the standard.

Our engineers will help at all stages:

- Development of 2D/3D models in AutoCAD, SolidWorks, CorelDraw

- Optimizing cutting to minimize waste

- Correction and conversion of drawings for cutting

- Technological audit of your project

We can make a sample from a photo or sketch from scratch.

We will apply individual logos, markings, serial numbers, QR codes, etc.:

- Deep and surface engraving of metals

- Marking on aluminum, steel, stainless steel, titanium, etc.

- Individual design, fast replication

- Industrial marking for serial products

Contrasting and durable laser marking is resistant to abrasion and corrosion.