Design and 3D Modeling

The first and most crucial stage, where the quality of the future product is established. We turn your idea, sketch, or sample into a precise 3D model optimized for injection molding.

- CAD Model Development: Creating a three-dimensional model in engineering software (SolidWorks, AutoCAD) considering all requirements.

- DFM Analysis (Design for Manufacturing): Checking the model for manufacturability. We analyze drafts, wall thickness, and reinforcing ribs to avoid molding defects (sink marks, warping, short shots).

- Mold-flow Analysis: Software simulation of the mold-filling process with molten plastic to determine the optimal location of gates and vents.

- Prototyping: Printing prototypes on a 3D printer (FDM, SLA) to evaluate ergonomics, assemblability, and appearance before launching expensive tooling.

Thorough design saves up to 30% of the budget by preventing errors and mold rework.

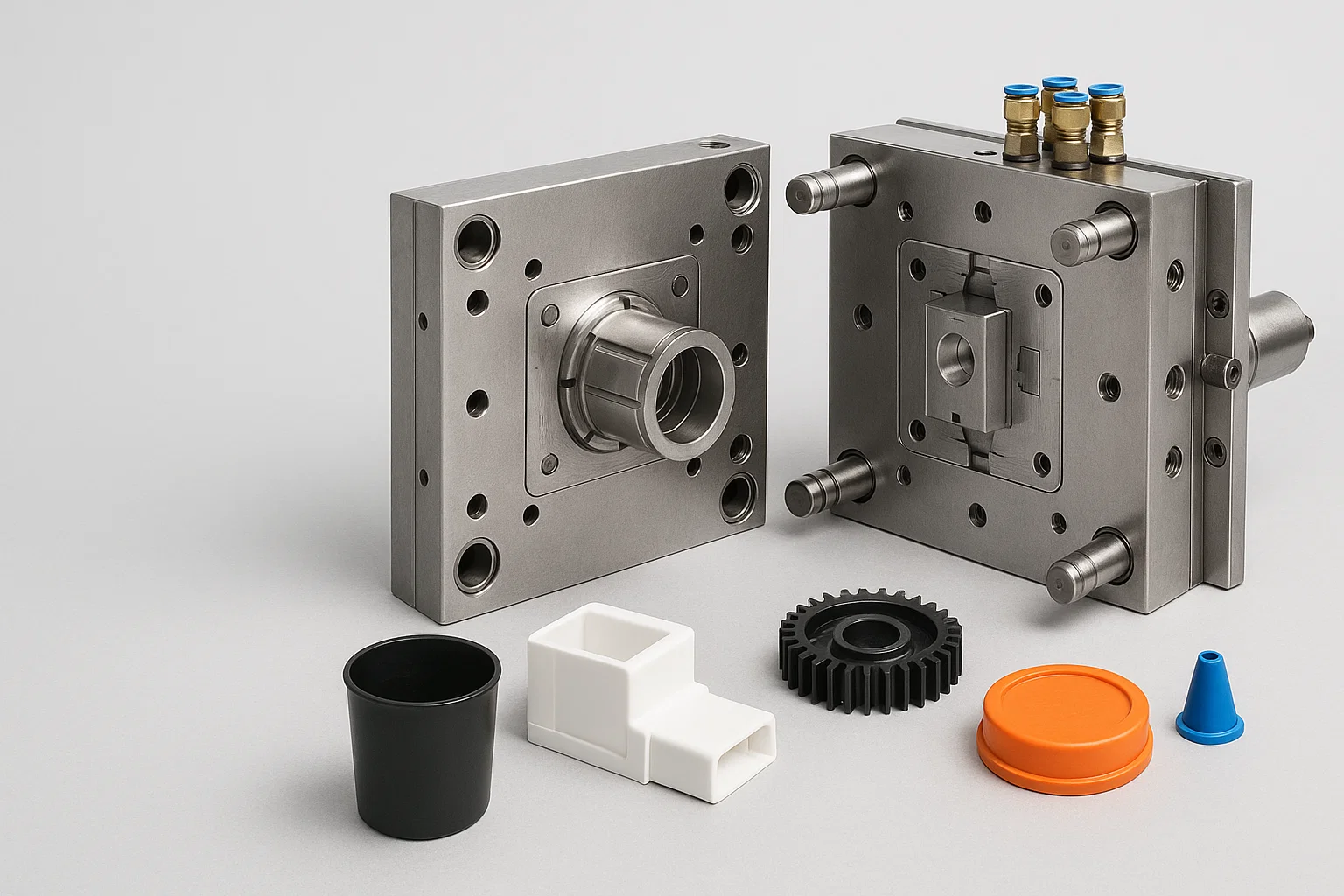

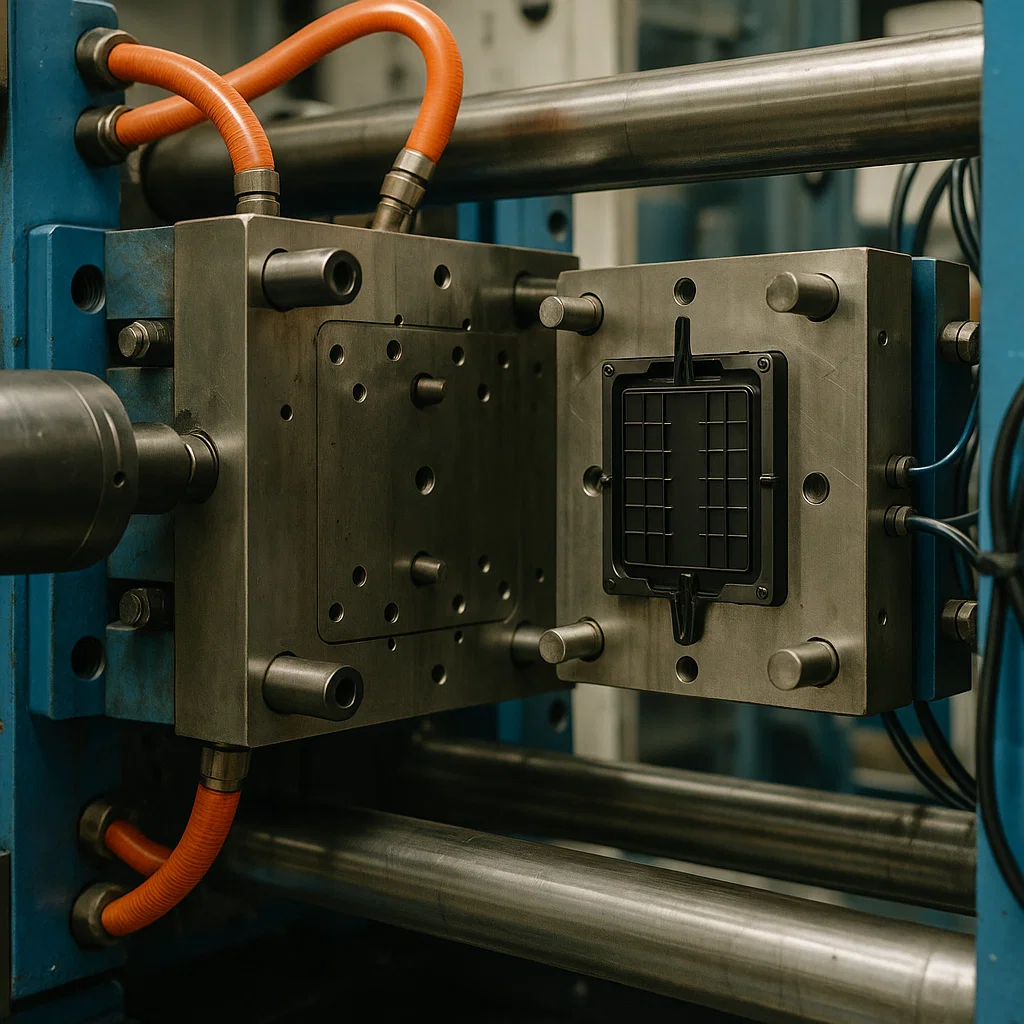

Mold Manufacturing and Maintenance

The heart of injection molding is the mold. Its quality directly affects the precision and lifespan of serial production. We manufacture tooling in our own tool shop.

- CNC Machining: Milling of forming plates, cores, and cavities on high-precision CNC machines.

- Electrical Discharge Machining (EDM): Creating complex reliefs, sharp corners, and textures that cannot be achieved by milling.

- Polishing and Assembly: Finishing working surfaces to the required roughness (up to a mirror finish) and precise assembly of all mold components.

- T1 Testing: Conducting the first mold trials on an IMM, obtaining T1 samples, and checking them for compliance with drawings.

- Warranty and Maintenance: We provide a warranty for the mold’s lifespan (e.g., 500,000 cycles) and perform its cleaning, repair, and maintenance.

Result: reliable tooling, ready for millions of shots.

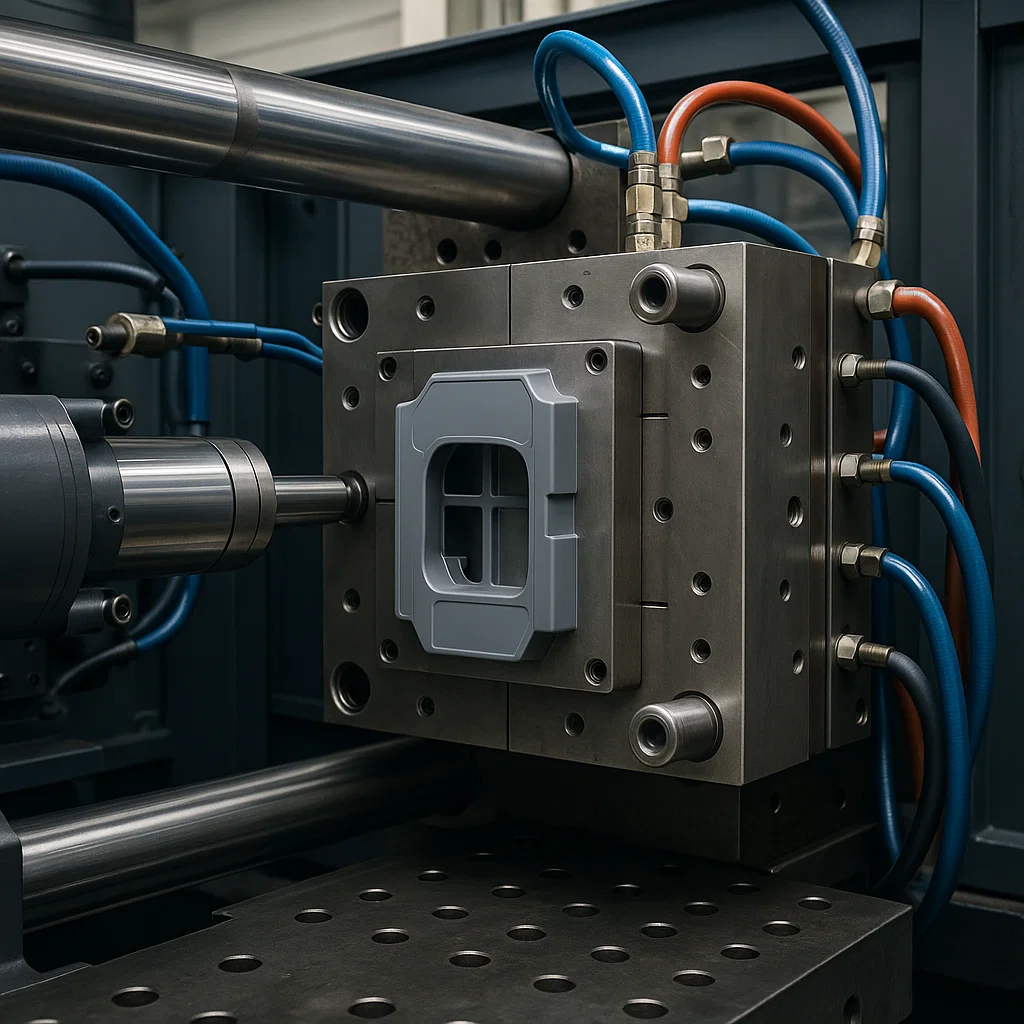

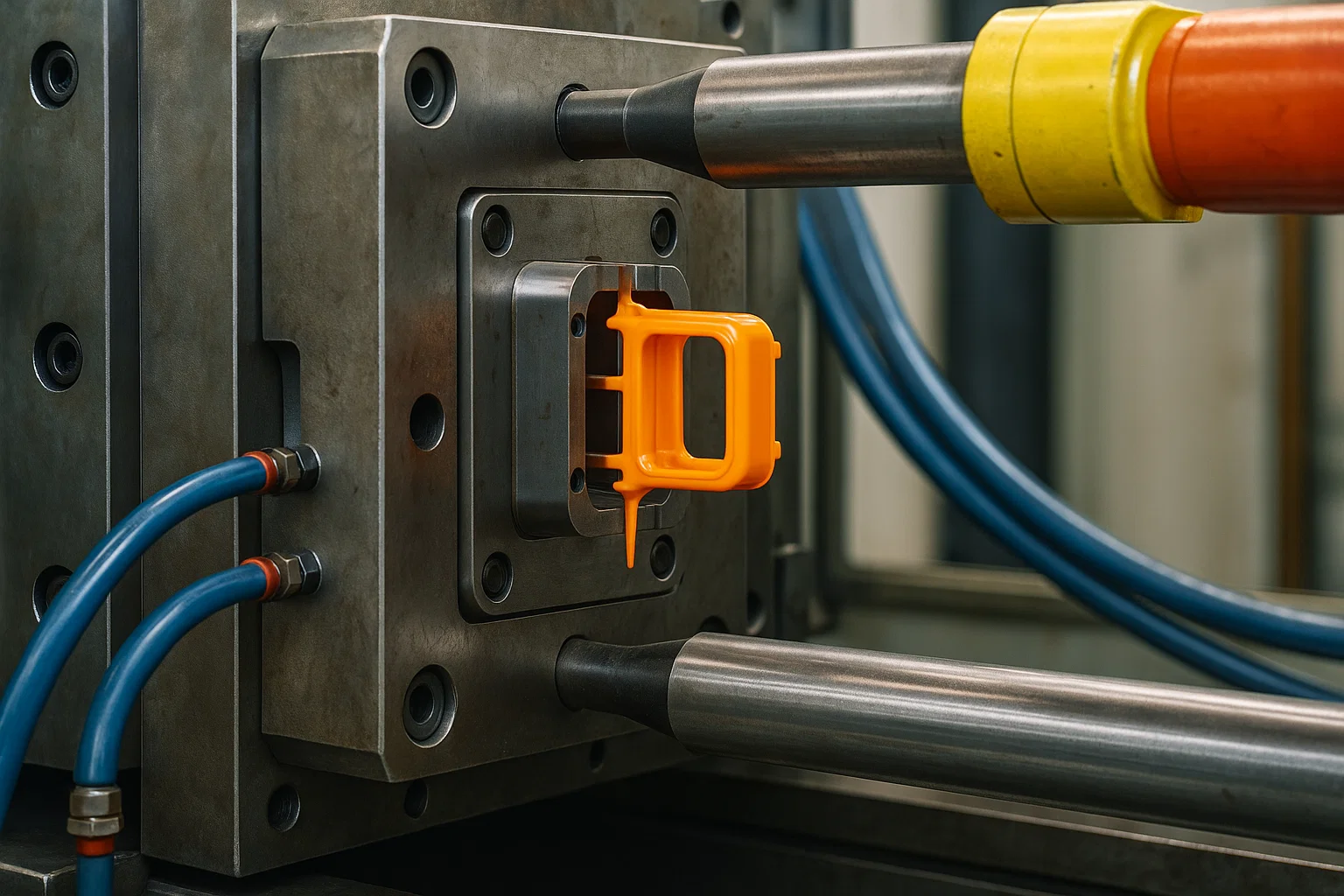

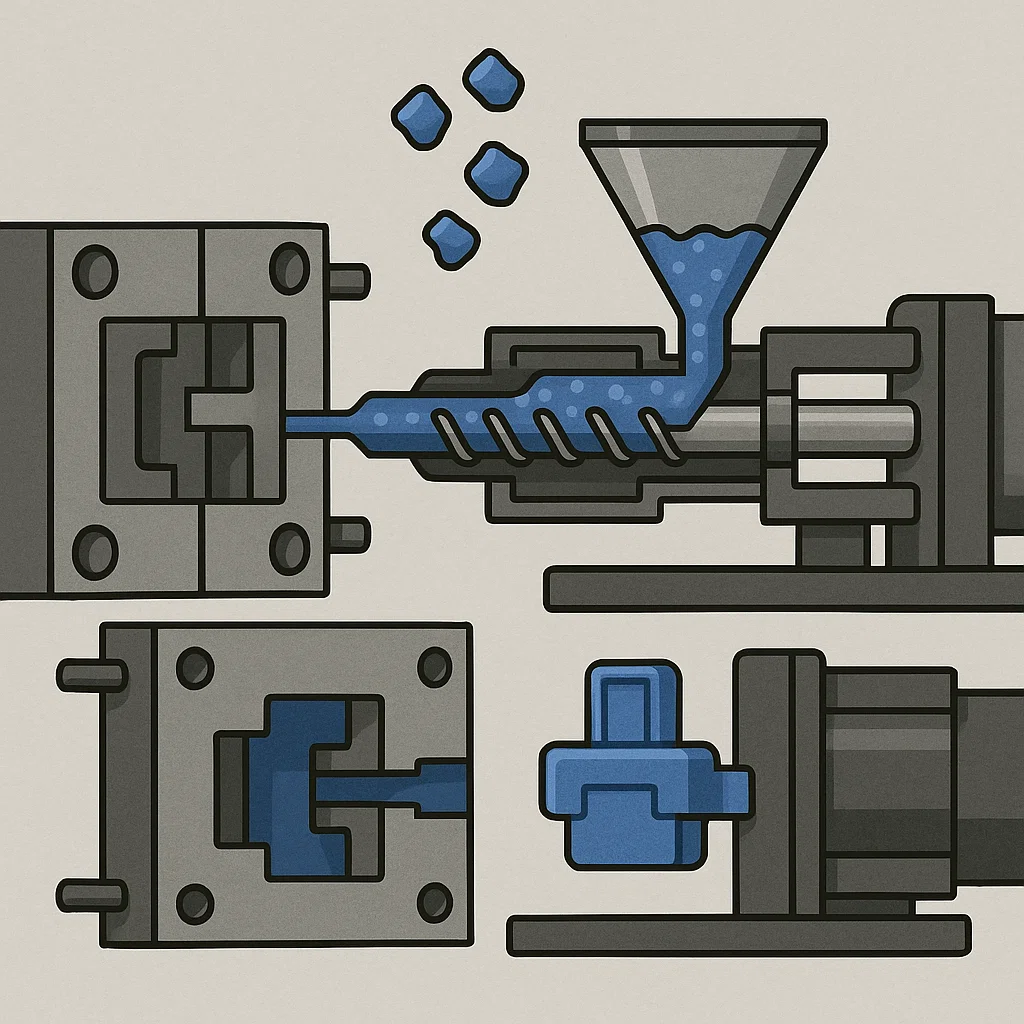

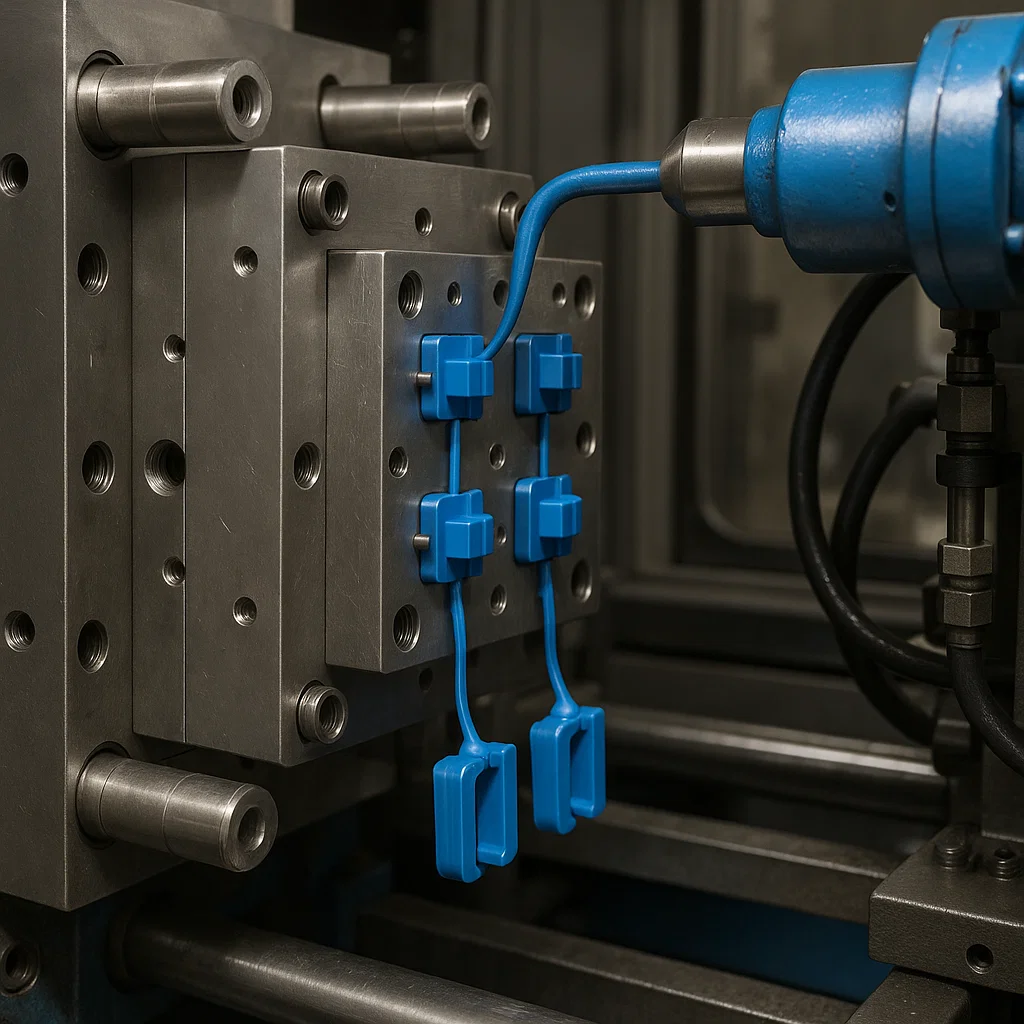

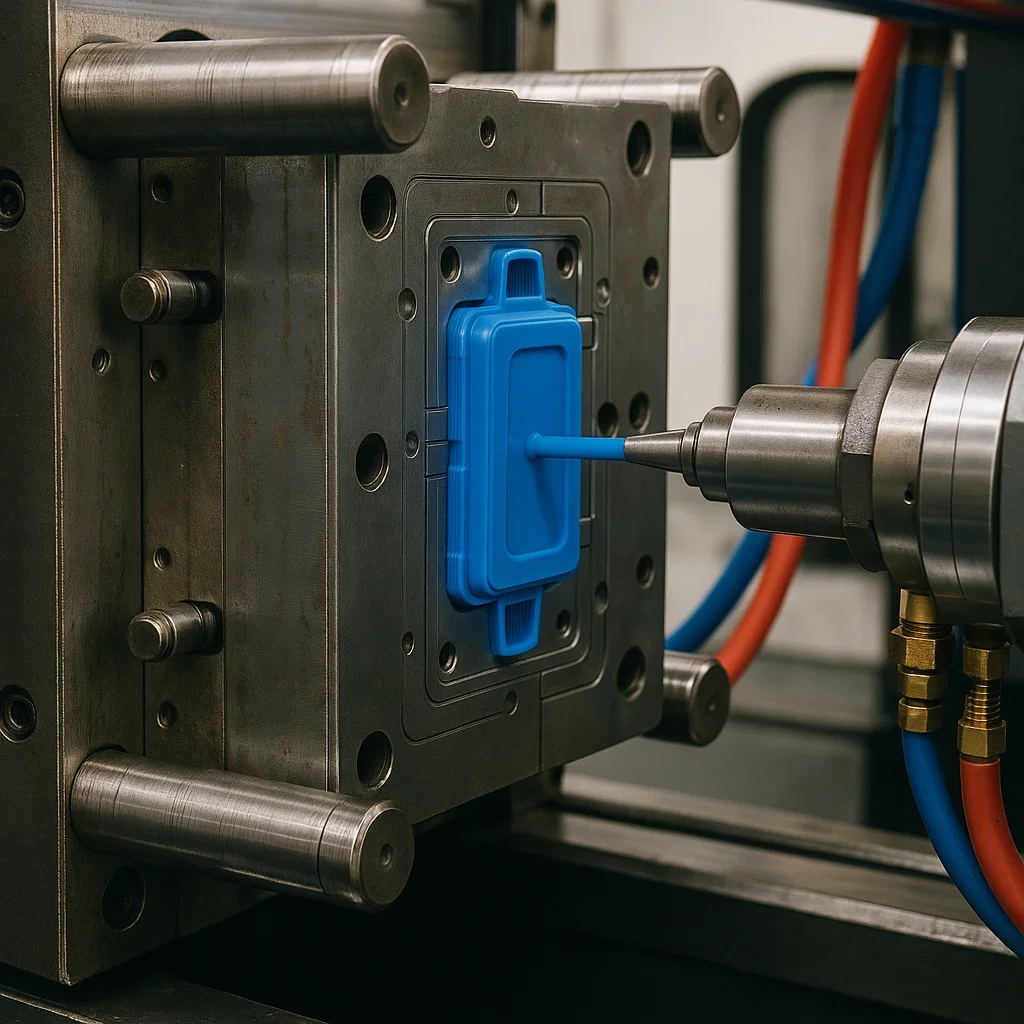

Serial Injection Molding

Our workshop is equipped with modern injection molding machines (IMMs) with a wide range of clamping forces. This allows us to produce both miniature parts and large housing components.

- Raw Material Selection and Preparation: We work with all types of thermoplastics (PP, ABS, PC, PS, PE, PA, POM, etc.). Before molding, the raw material undergoes mandatory drying in vacuum hoppers.

- Automation: The molding process is highly automated. Robotic arms extract the parts, ensuring cycle stability and preventing damage.

- Setup and Control: Our technicians select and control dozens of parameters (zone temperatures, injection pressure, holding time) to achieve perfect casting quality.

- 24/7 Operation: Production runs in multiple shifts, allowing us to complete large orders in tight deadlines.

We guarantee 100% part repeatability from the first to the last item in a batch.

Secondary Processing and Assembly

Often, molding is just one of the stages. We offer comprehensive solutions so you receive a product that is completely ready for use.

- Ultrasonic Welding: Reliable and aesthetic joining of several plastic parts into a single unit.

- Image Application: Pad printing, silk screening, and laser engraving for branding, marking, or instructions.

- Assembly: Installation of hardware, seals, electronic components, and final product assembly.

- Packaging: Development and production of custom packaging (boxes, blisters, bags) and product packing.

You get a turnkey product from a single source, saving time on finding contractors.

Quality Control and Logistics

Our Quality Management System, certified to ISO 9001 standards, ensures strict adherence to technology at all stages.

- Incoming Inspection: Checking each batch of raw materials for certificate compliance.

- In-Process Control: Measuring key product parameters (geometric dimensions, weight) during production every 30-60 minutes.

- 3D Scanning: High-precision control of the finished product’s geometry and comparison with the reference CAD model.

- Final Inspection: A final 100% check of products for visual defects before packaging.

- Logistics: We organize secure packaging and delivery of finished products to your warehouse anywhere in the country.

Our Quality Control Department (QCD) is your guarantee that you will receive only high-quality products.